Basic TMS System

You get a lot of benefits just from putting in an independent multi-carrier Transport Management (aka Freight Management / Dispatch) System straight away:

- As a multicarrier system, you can process your consignments from the one system; saving time.

- Having visibility on pricing for all carriers from the one centralized system is helpful for processing orders and for reporting.

- The ability to select the least cost carrier for each consignment, with the press of a button, is a huge money saver, plus again you save time because you no longer have to get quotes from various systems for each consignment.

- EDI (Electronic Data Interchange) and API (Application Programming Interface) transfers of your manifest data means you can efficiently send all relevant data to all your carriers efficiently and with high accuracy; reducing the number of lost freight issues.

- Carrier compliant labels supports your carrier’s routing and delivery processes.

- Customer’s love receiving an Advance Shipping Notice (ASN) and your Call Centre will enjoy the reduction in freight queries as well.

- Central tracking from one system makes it easy for your staff to track late deliveries regardless of which carrier the consignment was assigned to, or from which warehouse site.

- Some distributors save massive amounts from auto consolidation of consignments, e.g. less basic charge fees, absorbing the rounding up of minimum fees.

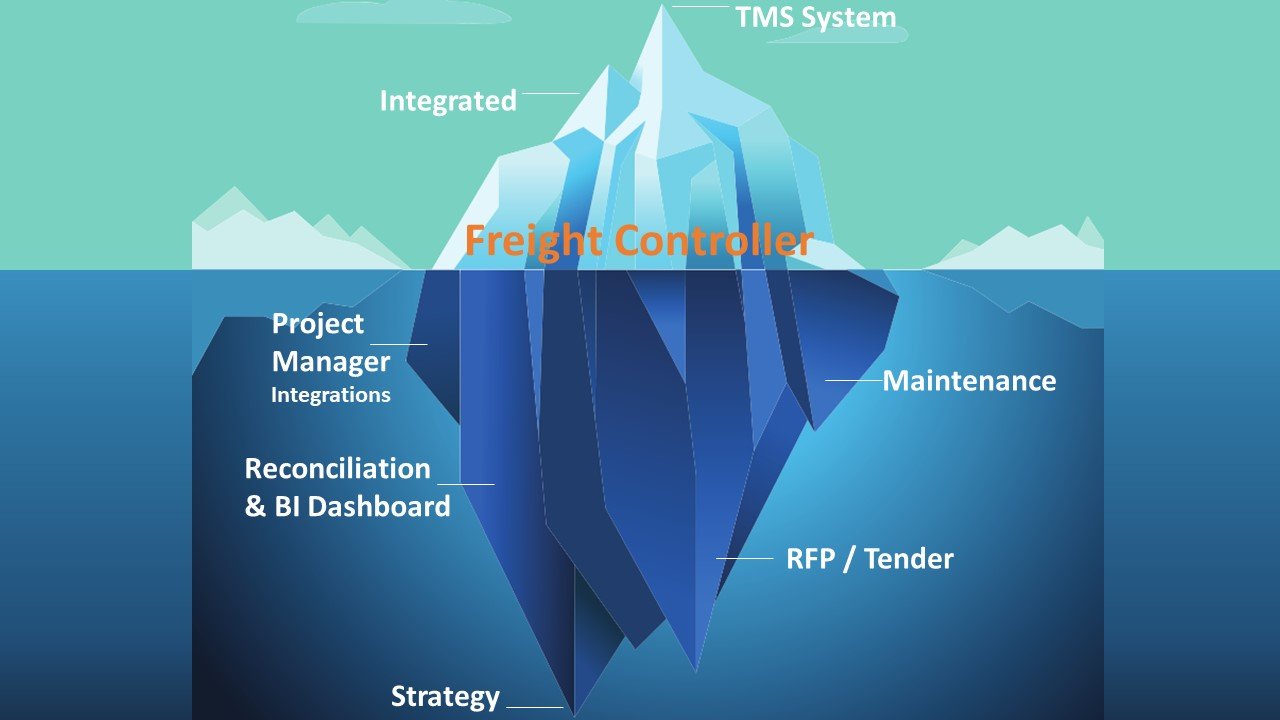

But that’s just the beginning of what you can get out of a TMS system.

A well-known applicable saying is: “A tool is only as good as the person who uses it.”

Yes, putting in a new TMS system will initially have a fairly big, positive impact, but it’s just the tip of the iceberg.

Integration

Integration with a WMS (Warehouse Management System), ERP (Enterprise Resourse Planning), Accounting, or Ecommerce system, for medium and high-volume users, is another level of improvement you can access.

- Increased automation, (beyond a manual multi-carrier system which can be 30 seconds to two minutes), can be a further two minutes saved per consignment.

- This enables higher throughput with the same amount of resources and can ‘bake in’ some scalability for your business as it grows.

- Integrations will reduce duplications, for example of ‘sales order header data’ having to be retyped into the TMS system to jump the gap from your ERP system to your dispatching system with the order.

- You will also reduce the incidences of human error: mistyped weights, dimensions, address details; leading to more accurate freight pricing and supporting your carriers for improving their delivery KPIs; leading to a happier customer base.

- You can create a ‘single source of truth’ if desired with exported data from the TMS being mapped to your WMS of ERP system.

Again though, we still see this as an ‘above the waterline’ aspect of a TMS system.

An integrated TMS system is no doubt another step towards best practice for most distributors, but there’s more to it than the ‘on the surface’ benefits we’ve outlined thus far.

Freight Project Management

First of all, what’s important with a supply chain integration project is ensuring you have the right people supporting you with this.

Consultants that:

- will conduct a thorough consulting & scoping process to create an optimal system

- sometimes challenge you to reach what is best practice for your business

- think through the potential limitations of the changing landscape for your business and the freight industry in general

- have in-depth logistics & operational knowledge from certification and decades of experience; going beyond mere technological knowledge

- will also support the implementation beyond the Go-Live date.

Whether it’s a partial integration, or a complex, staged integration with complex business rules and modifications to match a complex distribution system, getting it right the first time is key to a happy productive workplace and a strong ROI (Return On Investment).

Not all vendors will have the level of knowledge and the level of care to guide you through this process and deliver on your vision.

System Maintenance

Maintenance Includes:

- Updating rates every time there is a change

- Dealing with monthly fuel levies for accurate pricing

- Finding and eliminated errors with pricing

- Ensuring your Freight Mark Ups support your sales margins

- Are Group & Cost Centres input when needed? Are they kept up to date?

- Are you accurately assigning costs to the relevant customers & divisions for each consignment in your Freight Recovery efforts?

Maintenance is a bit like housework; thankless often dull but necessary work to keep things running smoothly.

Does your team have time to take their focus off their core tasks to deal with these important but not urgent tasks?

These backend software maintenance requirements are definitely ‘under the surface’ but they very much support your daily freight activity.

They keep your prices accurate to ensure you have high visibility on your freight costs.

Supporting your Business Intelligence Reporting and therefore supporting your daily tactics and long-term strategies.

Carrier Invoice Reconciliation & Business Intelligence Dashboard / Reporting

From Maintenance to Carrier Invoice Reconciliation (CIR) & Business Intelligence (BI) Dashboard & Reporting is a logical step.

Do you check carrier overcharges, on every consignment?

Are you immediately aware of any unauthorized rate charges?

Errors can occur internally with poor or irregular backend maintenance; through insufficient guidelines; through user error, and externally through human error or system changes via your carrier or third-party supplier.

Freight costs are typically at 10% of a business’s costs (sometimes more); you should accurately know your costs to serve and know them in detail.

Accurate pricing supports accurate B.I. Reporting and ensures that the steps you take to improve your freight business processes are the right steps; taking you in the right direction and not leading you ‘up the garden path’ because you are being misguided by unclean data.

You should be able to DIY these processes within your TMS and you should be supported in training to get the most out of the software functions for these processes. But these internal systems are not accurate and comprehensive as outsourcing to a freight consultancy. We have created a checklist for a DIY process.

And, if you don’t run these reconciliation reports weekly, you will not be alerted straight away of errors, when they crop up, and you will pay more than you should. For each week you don’t check, those pricing errors will accrue and will become more and more difficult to wind back through rebates.

If you don’t trouble shoot the pricing errors, or unwarranted surcharges; if you don’t have the right people with extensive knowledge on all tier 1, 2 & 3 carriers’ systems; if your accounts people don’t understand the myriad of freight costing methods through cubic conversions and accessorials and so on; and your logistics department can’t afford the time to do this, then these issues will compound negatively over time.

Do you have the automated systems look at the granular data with reconciliation, do you couple that with expert clerical oversight squeezing the last amount of value out of this process?

Is your Freight Cost Data generated post reconciliation for the most accurate insights for guiding your business strategies?

Is this feeding into a data warehouse & interactive Dashboard where you can drill down to collect all insights and create tailored reporting when needed?

Are they facilitated by a team of freight experts, or are they just stored away to be looked at when you notice an issue and want to track it back to its source?

Freight RFP / Tender

Having accumulated centralized, historic freight manifest data, invoicing data, you then have a store of data from which to profile and benchmark your freight against industry standards.

This enables a more accurate, more detailed predictive modelling freight review process; taking out the guesswork for any changes you are looking to implement.

“The best predictions of future behaviour is based on past behaviour.” That historic freight data is key to increasing the accuracy of any freight review changes you implement.

Some TMS systems support this to a degree but further support can be found from those vendors or consultants who utilise niche freight systems to efficiently process all of your incumbent carrier pricing details against a myriad of carefully selected prospective carriers as per the insights that can be gleaned from your freight profile.

Those with strong carrier relations built over decades can ensure you get the most out of the negotiation and implementation processes.

If you are interested in exploring a turnkey freight solution that can generate the savings to build your supply chain platform, then you need to speak with a freight consultancy, not a freight technology, company.

A freight management consultancy can bring their suite of ‘backend’ or inhouse freight management systems to enhance the RFP or Tender process, to efficiently and cost effectively ensure that you get the most comprehensive and accurate review process available.

Our system can crunch 100,000 consignments across multiple data sets within a day or two. Enabling our analysts to provide detailed, accurate range of reports for selecting the best matched carriers in price and service for your business moving forward. It doesn’t matter how many carriers, or how complex your freight, when we combine our freight system smarts and our analysts’ expertise; if we undertake a free no obligation preliminary freight review, we guarantee the results.

Freight Management Strategy

Supported by all of these freight tactics and reinforcing those tactics is your freight business strategy. Having control of your strategy is only possible from having full visibility on all aspects of your freight business processes.

Long-term strategies leads to an optimized freight and logistics department. Such long-term strategies are best supported through trusted business partnerships that go beyond mere software solutions.

Such strategies are best served through a continuous improvement methodology that draws upon the whole iceberg of a TMS system for ensuring that you are recalibrating your path towards best practice as you take into account the internal and external changes occurring in your business, the freight industry, and the wider economic environment.

TMS vendors do not go to these depths. Their systems may support them, but they cannot quite reach to this inverted tip of the iceberg to provide a holistic, turnkey solution for supporting your whole freight & logistics operations.

When choosing a partner for this journey it makes sense to turn to a company that has decades of experience from which you can tap into as and when needed to assist you with optimizing your freight management processes, whilst you focus on your core business and keeping your customers happy.

As always, if you would like to learn more about how to implement and get the most out of a TMS, please contact us and we would be glad to support you with this endeavour.